Most Popular PRoducts

Aluminium Galvanized Sheets

Price 20000-200000 INR/ Piece

MOQ : 10 Pieces

Aluminium Galvanized Sheets Specification

- Roof Material

- Suitable for roofing and cladding

- Technics

- Cold rolled and continuous hot-dipped galvanizing

- Features

- Highly durable, lightweight, reflective surface

- Usage & Applications

- Construction, roofing, cladding, ducting, fabrication, industrial panels

- Surface Treatment

- Galvanized and aluminium zinc coated, smooth or lightly embossed

- Height

- As per sheet size, typically 0.3 mm to 2.0 mm thickness

- Material

- Aluminium Galvanized Steel

- Tile Material

- Aluminium and Zinc Alloy Coated Steel

- Tile Type

- Flat Sheet

- Type

- Galvanized Sheet

- Size

- Customizable, typically 4 ft x 8 ft (1220 mm x 2440 mm)

- Shape

- Rectangular

- Pattern

- Plain or Corrugated

- Heat Transfer Coefficient

- Low, good thermal reflectivity

- Thickness

- 0.30 mm to 2.0 mm

- Length

- 2000 mm to 3050 mm (custom sizes available)

- Width

- 900 mm to 1250 mm

- Fire Resistance

- Non-combustible, excellent fire performance

- Edge Type

- Mill edge, slit edge or trimmed

- Gloss

- Semi-gloss to matte finish (depends on treatment)

- Standard

- ASTM, BS, JIS, IS, EN

- Yield Strength

- 240 - 550 MPa

- Service Life

- 15 - 30 years depending on environment

- Tensile Strength

- 270 - 700 MPa

- Packing Type

- Standard export packaging, bundled or palletized

- Coating Mass

- AZ50 to AZ150 (g/m)

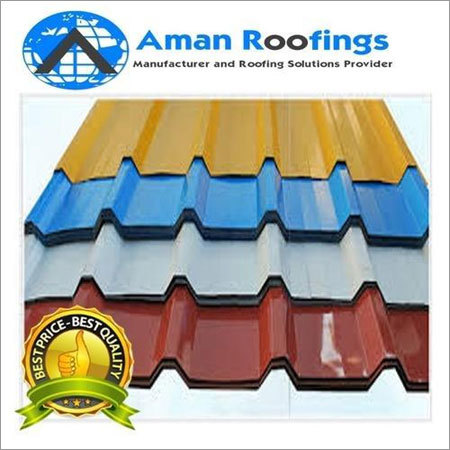

- Color

- Metallic Silver (natural), color coated options available

- Weight

- Approximately 2.36 kg/m at 0.3 mm thickness

- Rust Resistance

- Excellent, superior to conventional steel sheets

- Hardness

- HRB 6085

Aluminium Galvanized Sheets Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 15 Pieces Per Day

- Delivery Time

- 1 Days

About Aluminium Galvanized Sheets

Aluminium Galvanized Sheets are high in strength and sturdy enough to bear heavy loads and adverse weather condition. Owing to robust design, abrasion & temper resistance and seamless surface finish, these are perfect to be utilized in multiple construction as well as civil engineering works. Made available in different variants of grade, thickness, width, pattern and colour coating, such sheets are convenient to fix on metal framework due to its dimensional stability and lightweight. Aluminium Galvanized Sheets are offered at approx. price of Rs. 54 per kilogram.

Superior Rust and Fire Resistance

Aluminium Galvanized Sheets deliver exceptional rust and fire resistance due to their aluminium-zinc alloy coating and non-combustible nature. This makes them ideal for environments requiring long-term protection and safety, both for interior and exterior applications. Their robust coating enables superior endurance against harsh weather, moisture, and temperature fluctuations.

Versatile Finishes and Customizable Sizes

Choose from a variety of surface treatments, including natural metallic silver and color-coated options, available in plain or corrugated patterns. Standard sizes typically include 4 ft x 8 ft, but custom dimensions are readily available to suit project-specific requirements. The semi-gloss to matte finish enhances architectural appeal while maintaining practicality.

Multi-Purpose Industrial and Construction Use

These galvanized sheets are suited for roofing, cladding, ducting, and fabrication projects. Their high reflectivity, light weight, and durability make them safe and effective for use in industrial panels and modern construction, ensuring reliable performance with reduced maintenance over decades.

FAQs of Aluminium Galvanized Sheets:

Q: How are Aluminium Galvanized Sheets produced?

A: Aluminium Galvanized Sheets are manufactured using cold rolling and continuous hot-dipped galvanizing processes, which involve coating steel sheets with an alloy of aluminium and zinc. This coating provides superior corrosion resistance and ensures a durable, long-lasting surface.Q: What are the main benefits of using these sheets over conventional steel sheets?

A: These sheets offer outstanding corrosion and fire resistance, a longer service life of 1530 years, and are lightweight for easier handling and installation. Their reflective surface also improves thermal efficiency, making them more advantageous than traditional steel sheets.Q: When should I choose a mill edge, slit edge, or trimmed edge sheet?

A: The edge type depends on your projects specifications. Mill edge sheets are as-produced and may have slight irregularities, while slit and trimmed edge sheets provide smoother, more precise edges suitable for visible architectural applications or precise fitting requirements.Q: Where are Aluminium Galvanized Sheets most commonly used?

A: These sheets are widely used in construction for roofing, cladding, ducting, and industrial panel fabrication. Their rust resistance and fire repellence make them ideal for both residential and industrial environments, especially where durability is a priority.Q: What is the typical process for packaging and transporting these sheets?

A: Sheets are packed in standard export packaging, either bundled or palletized, to ensure safe and secure transportation. This method minimizes damage during transit and storage, maintaining the products integrity until installation.Q: How do I select the right sheet thickness and coating mass for my project?

A: Selecting the correct thickness (ranging from 0.30 mm to 2.0 mm) and coating mass (AZ50AZ150 g/m) depends on your projects structural load requirements and the environments exposure conditions. Thicker sheets and higher coating masses are recommended for harsher or more demanding settings.Q: What is the expected service life and durability of these sheets in different environments?

A: With proper installation, these sheets can last between 15 and 30 years. Their superior rust and fire resistance allow them to withstand challenging climates, making them a reliable long-term choice for various industrial and construction applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Roofing Sheet Category

Galvanized Sheet

Price 92.25 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Galvanized Sheet

Thickness : 2.5 Millimeter (mm)

Surface Treatment : Coated

Technics : Cold Rolled

Tile Profile Roofing Sheet

Price 110 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Stainless Steel

Surface Treatment : Coated

Technics : Cold Rolled

Plastic Roofing Sheet

Price 85 INR / Square Foot

Minimum Order Quantity : 50 Square Foots

Thickness : 412 Millimeter (mm)

Surface Treatment : Coated

Technics : Cold Rolled

Color Coated Profile Roofing Sheet

Price 20000-200000 INR / Piece

Minimum Order Quantity : 10 Pieces, ,

Material : Aluminium, Other

Thickness : 1.21 Millimeter (mm)

|

AMAN INFRA PROJECTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry