True Roof C & Z Purlin

Price 20000-200000 INR/ Piece

True Roof C & Z Purlin Specification

- Surface Treatment

- Hot Dip Galvanized

- Technics

- Cold Rolled, Roll Formed

- Roof Material

- Steel

- Height

- Up to 300mm (varies as per design)

- Features

- Corrosion Resistance, High Strength, Lightweight

- Usage & Applications

- Pre-Engineered Buildings, Factories, Industrial Sheds, Warehouses, Roofing, Wall & Cladding Support

- Material

- High Tensile Galvanized Steel

- Type

- C & Z Purlin

- Size

- Customizable (commonly 80mm to 300mm web)

- Shape

- C Shape, Z Shape

- Pattern

- Plain or Slotted

- Heat Transfer Coefficient

- Low, depends on thickness

- Thickness

- 1.2mm - 3.0mm

- Length

- Up to 12 meters (custom lengths available)

- Width

- As per specifications (typically 35mm to 75mm flange)

- Tolerance

- High Dimensional Accuracy

- Installation

- Easy Installation, Pre-punched Holes Available

- Maintenance

- Minimal Maintenance Requirement

- Standard

- IS 811 & IS 12778 Compliant

- Packaging Details

- Bundle Packing, Protective Wrapping

- Finish

- Zinc Coated, Smooth

- Environmental Resistance

- Resistant to Humidity & Harsh Weather

- Color

- Silvery-Grey (Galvanized Natural Color)

- Yield Strength

- 250 MPa/ 345 MPa / 550 MPa (as required)

True Roof C & Z Purlin Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 15 Pieces Per Day

- Delivery Time

- 1 Days

About True Roof C & Z Purlin

Introduction

Yield Strength : 245 Mpa to 345 Mpa Type: Bare, Primer coated, Galvanized, Painted C and Z purlins made of hot rolled

coils are degreased, phosphate and then primer finished with Chrome Red-Oxide Paint-Matching Test as requirement of

IS: 4777 and IS : 2074. Special treatment to combat severe atmospheric corrosion can be offered. We also offer purlins

in galvanized coated steel in 120 GSM/175 GSM/275 GSM coating as per customer requirement.

Superior Strength and Flexibility

True Roof C & Z Purlins boast high yield strength (250 MPa, 345 MPa, or 550 MPa), ensuring durable support for a variety of structural projects. Customizable in dimensions, they suit unique architectural requirements and complex engineering designs, enhancing overall stability and performance in both industrial and commercial applications.

Corrosion-Resistant Galvanized Finish

These purlins are hot dip galvanized, offering a protective silvery-grey coating that dramatically improves their resistance to humidity, environmental pollutants, and harsh weather. This guarantees a long service life with minimal maintenance and enduring aesthetic appeal.

Efficiency in Installation and Maintenance

Engineered for practicality, True Roof C & Z Purlins come with pre-punched holes, precision tolerances, and are delivered in securely bundled packaging. This facilitates quick, easy onsite installation and integration, while the low-maintenance requirements reduce long-term costs and downtime.

FAQs of True Roof C & Z Purlin:

Q: How are True Roof C & Z Purlins typically installed in construction projects?

A: True Roof C & Z Purlins are designed for effortless installation. Pre-punched holes and high dimensional accuracy allow for rapid alignment and fastening, reducing labor time. Simply position the purlins on supporting structural members and secure them as specified in the project design.Q: What makes these purlins suitable for use in harsh and humid environments?

A: The hot dip galvanized zinc coating provides exceptional corrosion resistance, protecting the steel from moisture, chemicals, and extreme weather conditions. This ensures reliable performance in warehouses, factories, and locations prone to high humidity or harsh climates.Q: When should I consider using C Shape or Z Shape purlins?

A: Choose C Shape purlins for simple span applications where one purlin is supported between two points. Z Shape purlins are ideal when lapping is needed for longer spans or increased structural strength, thanks to their overlapping capability and versatility in continuous systems.Q: Where are True Roof C & Z Purlins commonly used?

A: These purlins are widely employed in pre-engineered buildings, industrial sheds, factories, warehouses, and as support for roofing, wall, and cladding systems. They are preferred wherever strong, lightweight, and corrosion-resistant support is essential.Q: What benefits do high tensile galvanized steel purlins offer over traditional options?

A: Compared to standard steel or timber, high tensile galvanized steel purlins deliver greater strength, lighter weight, and superior corrosion resistance. This not only ensures structural integrity but also makes them easier to handle and maintain, with a longer lifespan in demanding environments.Q: What is the process behind manufacturing True Roof C & Z Purlins?

A: True Roof C & Z Purlins are produced using cold rolling and roll forming techniques. High-tensile steel is shaped into C or Z profiles, cut to custom lengths, and hot dip galvanized to enhance durability and environmental resistance before packaging for delivery.Q: How does the customizable size range benefit project planners and engineers?

A: With widths, thicknesses, and lengths tailored to specification, engineers can ensure optimal load distribution and fit in any design. This flexibility streamlines project execution, maximizes material efficiency, and guarantees compatibility with diverse building architectures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tile Roofing Sheets Category

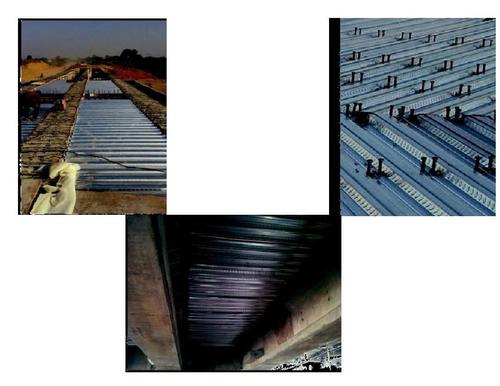

True Roof Steel Deck

Price 20000-200000 INR / Piece

Minimum Order Quantity : 10 Pieces

Thickness : 0.8 mm to 2.0 mm

Tile Material : Other, Galvanized Steel

Heat Transfer Coefficient : Low thermal conductivity

Height : 45 mm (Profile Height)

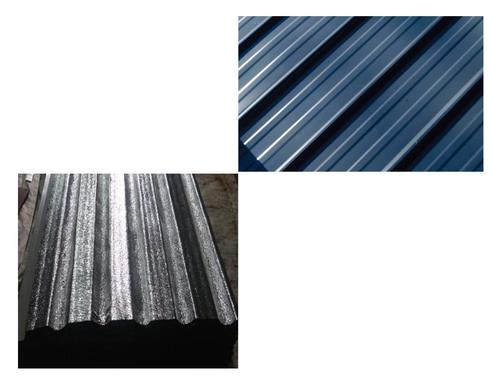

True Roof Hi Rib Profile Sheet

Price 20000-200000 INR / Piece

Minimum Order Quantity : 10 Pieces

Thickness : 0.40 mm 0.60 mm

Tile Material : Other, Galvanized Steel

Heat Transfer Coefficient : Low (Provides Good Insulation)

Height : 28 mm to 35 mm (Hi Rib Depth)

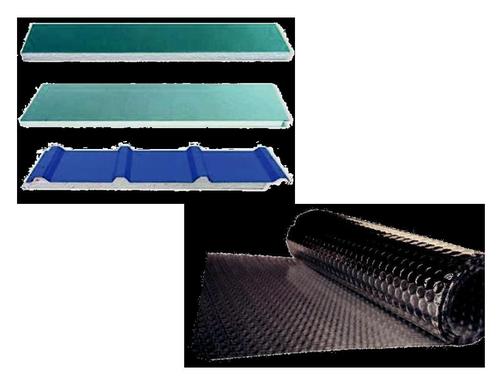

True Roof Insulation Sheets

Price 20000-200000 INR / Piece

Minimum Order Quantity : 10 Pieces

Thickness : 25 mm

Tile Material : Other, HighQuality Polystyrene

Heat Transfer Coefficient : 0.023 W/m.K

Height : 25 mm

True Roof Roofing Accessories

Price 20000-200000 INR / Piece

Minimum Order Quantity : 10 Pieces

Thickness : 0.3 mm 1.0 mm

Tile Material : Other, Galvanized Iron

Heat Transfer Coefficient : Low

Height : As per specification

|

AMAN INFRA PROJECTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry